At Three Brothers Auto Repair in New Jersey, we often hear drivers complain about rough idling, unexpected stalling at stop lights, or a sudden check-engine light. These issues can point to a failing idle air control (IAC) valve, which is responsible for regulating the engine’s idle speed. The IAC valve maintains a steady idle by controlling airflow at the throttle plate. When it malfunctions, you may notice erratic idle RPMs, stalling, or difficulty starting. As the IAC valve ages or carbon builds up, these symptoms may become more pronounced. In this article, we explain what the IAC valve does and how to recognize its failure symptoms. Understanding these signs can help our New Jersey customers know when it’s time to bring their car in for service.

- How the Idle Air Control Valve Works

- Common Symptoms of IAC Valve Failure

- Diagnosing and Repairing IAC Valve Issues

- Idle Control: Normal vs Faulty Behavior (Comparison)

- Why Prompt IAC Valve Service Matters

- What are the symptoms of a bad idle air control valve?

- Can an idle control valve cause jerking while driving?

- Can I clean my idle air control valve instead of replacing it?

- Can you drive with a bad idle air control valve?

How the Idle Air Control Valve Works

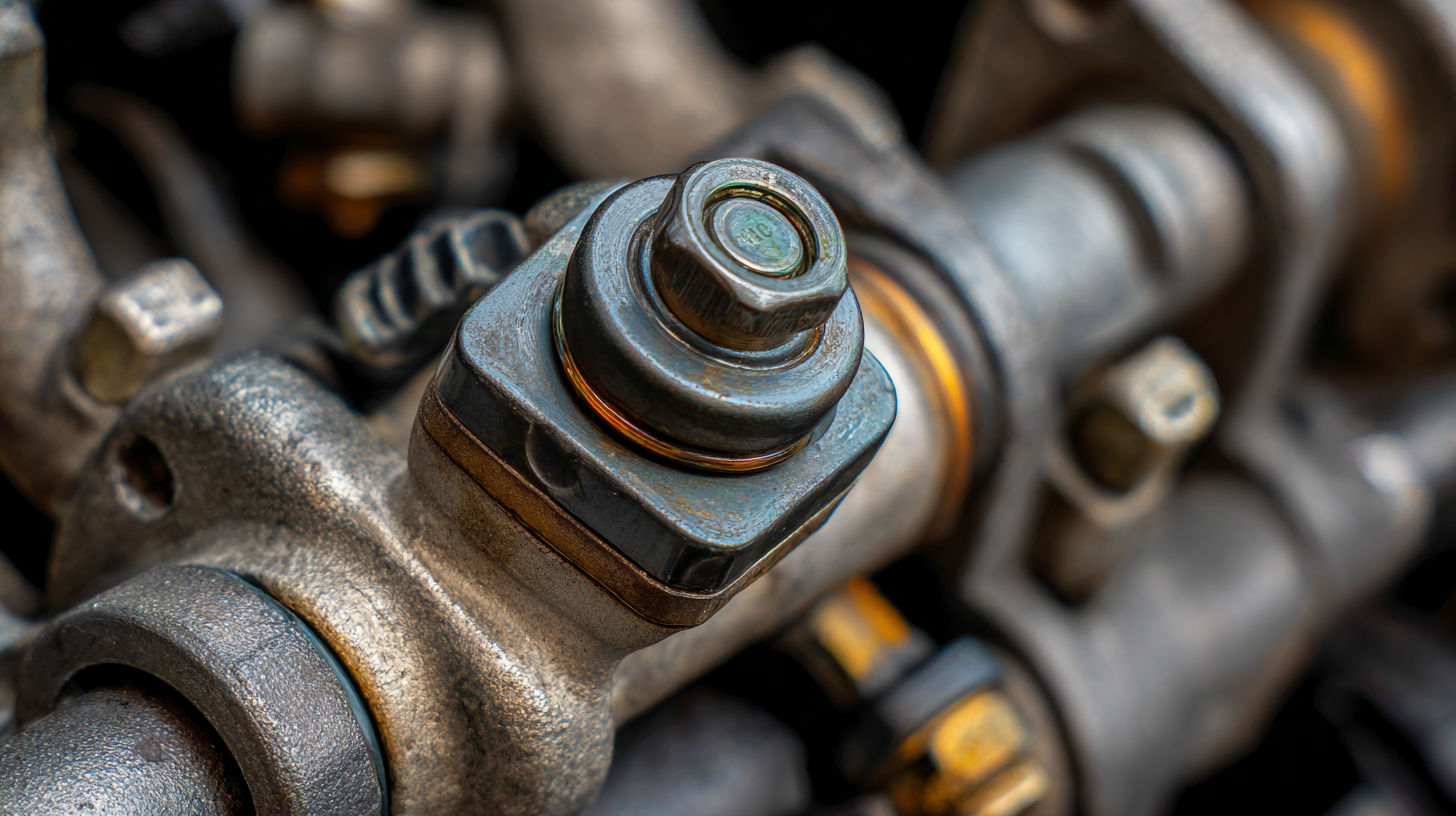

The IAC valve is a small but crucial part of the engine management system. It works with the vehicle’s computer to adjust airflow into the engine at idle. For example, when you turn on the air conditioning or use power steering, the IAC valve opens to allow more air and prevent the engine from stalling. On a properly working car, idle speed remains steady even when loads change. Many newer vehicles use electronic throttle control (drive-by-wire) instead of a separate IAC valve, but plenty of cars on the road (including many we service) still rely on the IAC. These valves can differ in design — some use stepper motors, others use a simple solenoid — but they all aim to maintain proper idle airflow. A healthy IAC ensures smooth acceleration and the correct air/fuel mixture under varying conditions. When an IAC valve fails, the lack of precise airflow control causes immediate issues. In practice, this means the idle can become erratic, jumping high or low, and engine performance may suffer.

Common Symptoms of IAC Valve Failure

When an IAC valve begins to fail, the engine’s idle and performance will often give clues. For example, you might notice the RPM suddenly surge or the engine stumble at idle. We advise drivers to watch for these common warning signs:

-

Irregular or fluctuating idle speed: The engine RPM may jump up and down or sputter at idle. You might feel the car shaking or hear the tachometer needle bouncing.

-

Engine stalling: A faulty IAC valve can cause the engine to stall when coming to a stop or even while idling. Our technicians frequently see cars suddenly die at traffic lights due to insufficient idle airflow.

-

Hard starting or no-start: If the IAC valve is stuck closed or open, it can upset the air/fuel mix on startup. The engine may crank but fail to fire, especially in cold conditions.

-

Illuminated Check Engine Light (CEL): The vehicle’s computer monitors idle control and will trigger the CEL if it detects a problem. An OBD-II scan often returns an idle control code (e.g. P0505).

These symptoms can also appear with other issues, so we look for multiple signs together. In our New Jersey shop, the combination of erratic idle, stalling, and a lit CEL usually means it’s time for an IAC inspection.

Diagnosing and Repairing IAC Valve Issues

Proper diagnosis is key to confirming an IAC problem. We recommend a systematic approach:

-

Scan and inspect: Begin with an OBD-II scan for trouble codes (for example, P0505 indicates an idle-control issue). Also inspect for vacuum leaks or a dirty throttle body. Leaks or carbon buildup can mimic IAC symptoms and should be fixed first.

-

Test the IAC valve: If diagnostics still point to the IAC, test the valve itself. An OEM scan tool can command the valve to open/close, verifying its response. Alternatively, a technician may bench-test the valve or measure its electrical resistance.

-

Clean or replace: Often a dirty valve is the culprit. We clean the IAC passages and throttle body to remove carbon buildup. If the valve is worn or fails electrical tests, replacement is necessary, using a quality part to restore proper idle control.

After any repair, we clear stored codes and test-drive the vehicle. Spotting the symptoms is only the first step; accurately diagnosing a faulty IAC valve is essential to repair it correctly and avoid additional damage. This careful process helps us fix the idle issue correctly and avoid more costly follow-up repairs.

Idle Control: Normal vs Faulty Behavior (Comparison)

To illustrate the difference, the table below compares engine idle behavior with a healthy IAC valve versus a failing one:

| Aspect | Normal IAC Valve | Faulty IAC Valve |

|---|---|---|

| Idle Speed | Steady, consistent RPM at idle | Irregular idle — RPMs jump, dip, or hunt |

| Engine Stability | Smooth, vibration-free idle | Rough or uneven idle; engine may shake or surge |

| Check Engine Light | Typically off (unless another issue) | Likely on; computer logs idle-control codes |

| Engine Stalling | No unexpected stalls at idle | May stall when coming to a stop or at idle |

| Starting and Idling | Easy starts; stable idle after start | Hard to start or may stall right after starting |

| Throttle Response | Normal acceleration and power | Hesitation or misfires under load |

This comparison highlights how a failing IAC valve affects everyday driving. If multiple aspects in the right column match what you experience, the IAC valve likely needs service.

Why Prompt IAC Valve Service Matters

Idle issues should not be ignored. At Three Brothers Auto Repair, we’ve helped many New Jersey drivers fix IAC valve problems before they become serious. If you notice any of the symptoms above — erratic idle speed, stalling, hard starting, or a check-engine light — bring your car to us. We can quickly diagnose the issue and clean or replace the IAC valve as needed. Early repair often avoids more costly damage later. Remember, routine maintenance (like cleaning the throttle body and idle passages) can help prevent buildup. A small idle issue can quickly escalate if ignored. Trust our team to keep your engine idling smoothly.

-

What are the symptoms of a bad idle air control valve?

A faulty IAC valve can cause rough idling, stalling, or fluctuating RPMs when your car is running. You may also notice your check engine light turning on.

-

Can an idle control valve cause jerking while driving?

Yes — if the valve sticks or fails, the air-fuel mixture becomes unstable, leading to jerking, hesitation, or surging during acceleration.

-

Can I clean my idle air control valve instead of replacing it?

In many cases, yes. Cleaning the valve can remove carbon buildup and restore function, but a severely damaged valve will need replacement.

-

Can you drive with a bad idle air control valve?

It’s not recommended. A bad IAC valve can make your car stall unexpectedly, especially when idling or stopping, which can be dangerous in traffic.